How Does an Electric Stacker Work? A Comprehensive MHE Guide

Share

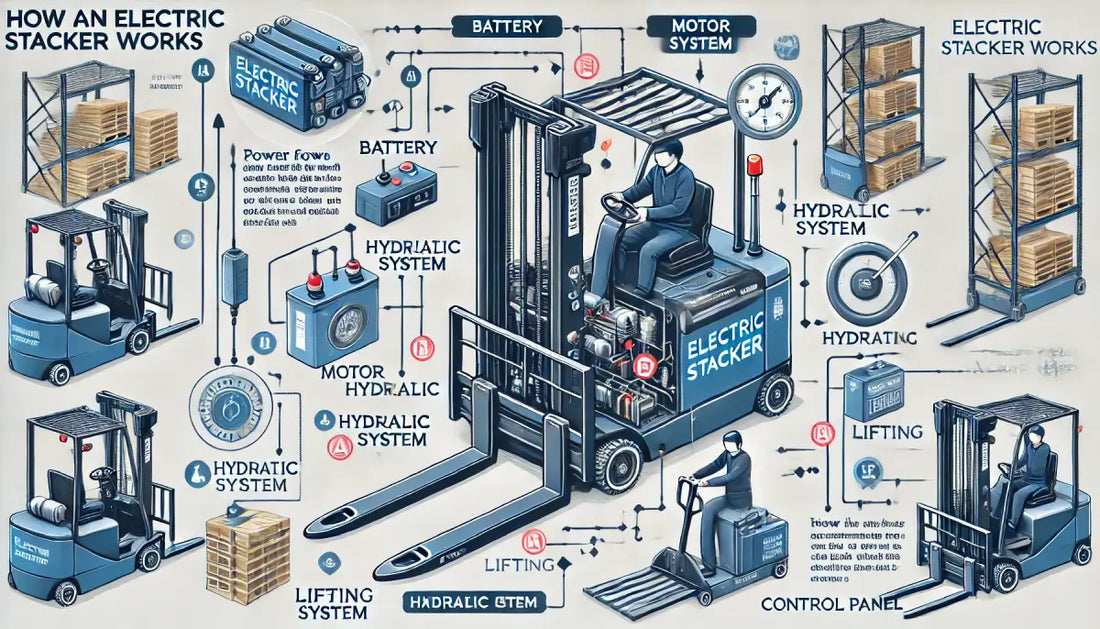

In warehouses and industrial environments, efficient material handling is crucial. The electric stacker is one of the most essential tools for lifting and stacking pallets. Designed to streamline operations, electric stackers provide a safer and more efficient way to handle heavy loads. How does an electric stacker work? If you're looking for high-quality electric stackers, check out Electric Stackers to find the right fit for your needs.

Understanding the Electric Stacker

An electric stacker is a motorized lifting device used in warehouses, distribution centers, and factories to move and stack pallets. Unlike manual pallet jacks, these machines operate with an electric motor, allowing for effortless lifting and transportation of heavy loads.

Key Components of an Electric Stacker

- Electric Motor – Powers the lifting and movement functions.

- Mast and Forks – Lifts and supports loads at varying heights.

- Battery Pack – Supplies energy to the motor.

- Control Panel – Includes buttons and levers for maneuvering and lifting.

- Wheels and Chassis – Provides stability and smooth movement.

- Safety Features – Emergency stop buttons and braking systems enhance operator safety.

How an Electric Stacker Operates

1. Powering Up the Stacker

Before using an electric stacker, the operator ensures the battery is sufficiently charged. Most models use rechargeable lithium-ion or lead-acid batteries that provide extended operational hours.

2. Positioning and Navigation

Operators control the stacker through a handle or tiller. With precise steering mechanisms, they can easily navigate narrow aisles and tight spaces, making electric stackers ideal for confined warehouse environments.

3. Lifting and Lowering Loads

Using the control panel, operators adjust the height of the forks. The electric motor lifts the load smoothly and securely, reducing physical strain on workers. The mast provides vertical stability to prevent tipping.

4. Transporting Pallets

Electric stackers are designed for efficient load transportation. Depending on the model, some stackers are walk-behind units, while others have a ride-on platform for the operator.

5. Stacking and Storing

Once the stacker reaches the designated storage location, the operator carefully lowers the pallet to its position. This allows for optimal warehouse organization and maximized storage capacity.

Types of Electric Stackers

There are different electric stacker models, each suited for specific tasks:

Walkie Stacker

A walk-behind electric stacker that offers maneuverability in small spaces. Ideal for light to medium-duty tasks.

Rider Stacker

Designed for higher productivity, the rider stacker includes a platform for the operator, making it easier to cover longer distances.

Straddle Stacker

With wide base legs for stability, straddle stackers can lift heavier loads without the risk of tipping.

Counterbalance Stacker

Similar to a forklift, the counterbalance stacker has no base legs, allowing for easy access to pallets placed on the ground.

Benefits of Using an Electric Stacker

Electric stackers offer several advantages over manual and hydraulic alternatives:

- Increased Efficiency – Motorized lifting reduces the time required to move pallets.

- Enhanced Safety – Built-in safety features minimize workplace injuries.

- Cost-Effective – Lower operating costs compared to forklifts.

- Eco-Friendly – Battery-operated, producing zero emissions.

- Compact Design – Ideal for narrow aisles and small storage spaces.

Using a Walkie Stacker to Unload a Truck

Yes, a walkie stacker can be used to unload a truck, but it depends on the truck’s design and dock height. Can you unload a truck with a walkie stacker? Walkie stackers are effective for unloading pallets in controlled environments but may not be suitable for all truck types.

Safety Tips for Operating an Electric Stacker

To ensure safe and efficient operation, follow these best practices:

- Conduct Pre-Use Inspections – Check the battery, brakes, and control panel before use.

- Wear Proper Safety Gear – Use gloves, safety shoes, and high-visibility vests.

- Follow Load Capacity Limits – Overloading can lead to equipment failure.

- Operate on Level Surfaces – Avoid sloped or uneven floors to prevent tipping.

- Use Designated Aisles – Keep clear paths for efficient movement.

Electric stackers are essential tools for efficient material handling in warehouses and industrial settings. Their motorized operation enhances productivity while ensuring workplace safety. Whether you need a walkie stacker or a counterbalance model, selecting the right equipment can improve operational efficiency. Investing in the right electric stacker will optimize your warehouse operations and enhance overall workflow management.