Can You Unload a Truck with a Walkie Stacker? Learn the Best Practices

Share

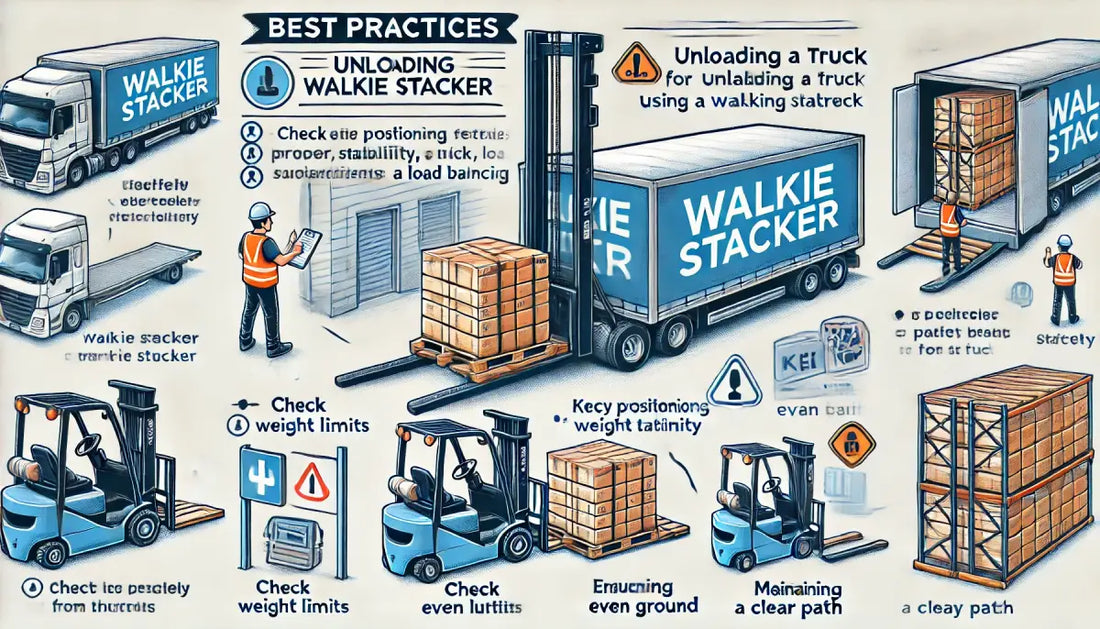

Regarding warehouse operations and material handling, efficiency and safety are top priorities. Many warehouse managers and operators ask: Can you unload a truck with a walkie stacker? The answer depends on several factors, including the type of walkie stacker, the truck design, and the overall working environment.

For a comprehensive selection of Electric Stackers that improve warehouse efficiency, visit Material Handling Equipment.

Understanding Walkie Stackers for Truck Unloading

Walkie stackers are versatile material handling machines designed to lift, transport, and stack pallets in warehouses, retail spaces, and industrial settings. Unlike forklifts, they are compact, battery-operated, and easy to maneuver in tight spaces. However, their ability to unload trucks depends on key factors such as:

- Truck Type: Box trucks, trailers, and flatbeds require different unloading methods.

- Dock Leveling: Unloading becomes easier if the truck is docked at an even level.

- Walkie Stacker Type: Some models are better suited for truck unloading than others.

- Load Capacity: Exceeding weight limits can compromise safety and efficiency.

Factors Affecting Unloading a Truck with a Walkie Stacker

1. Walkie Stacker Load Capacity and Reach

Most walkie stackers have a limited lifting height and weight capacity. If a truck has high sidewalls or deep interiors, the stacker might not reach the back of the truck. Choosing a model that can handle the required weight and reach is essential.

2. Pallet Access and Truck Design

- Dock-Height Trailers are the easiest to unload since the walkie stacker can roll in smoothly.

- Low-Deck Trucks: A dock plate or lift is necessary if the truck is lower than the warehouse dock.

- Pallet Positioning: Poorly positioned pallets can make unloading difficult.

3. Floor and Surface Considerations

Walkie stackers perform best on smooth, even surfaces. If a truck bed is uneven or obstructs, unloading may be challenging. Some models come with larger wheels to handle minor irregularities.

How to Safely Unload a Truck with a Walkie Stacker

To ensure safe and efficient unloading, follow these best practices:

- Assess the Load and Truck – Check pallet weight, placement, and truck alignment.

- Use Dock Leveling Equipment – If necessary, install a dock plate for seamless transition.

- Position the Walkie Stacker Correctly – Align with the pallets for smooth lifting.

- Lift and Transport with Care – Avoid sudden movements to prevent tipping.

- Ensure Operator Training – Only trained personnel should operate a walkie stacker.

Alternative Solutions for Efficient Unloading

If a walkie stacker alone is not sufficient for unloading a truck, consider additional equipment such as:

- Pallet Jacks: Ideal for moving loads to a more accessible location.

- Dock Levelers: Bridges height gaps between truck and warehouse floor.

- Electric Forklifts: Suitable for higher lifting capacity needs.

Benefits of Using a Walkie Stacker for Truck Unloading

Even with some limitations, walkie stackers offer several advantages:

- Cost-Effective: More affordable than forklifts with lower maintenance costs.

- Compact and Maneuverable: Ideal for tight warehouse spaces.

- Eco-Friendly: Battery-powered operation reduces emissions.

- Improves Workplace Safety: Reduces the risk of accidents when properly used.

Key Considerations When Choosing a Walkie Stacker

Before deciding whether a walkie stacker is suitable for truck unloading, consider the following:

- Lifting Height Requirements – Ensure the stacker can reach the required height.

- Weight Capacity – Check the manufacturer’s specifications.

- Flooring Conditions – Smooth, even surfaces work best.

- Operator Experience – Proper training is crucial for safety.

For more insights on how does an electric stacker work, explore our detailed guide.

Achieving Long-Term Efficiency

Proper maintenance is essential for keeping walkie stackers in optimal condition. Regular battery checks, lubrication, and component inspections ensure longevity and safety. For a detailed guide on maintaining electric stackers, refer to our maintenance best practices.

Final Thoughts: Can You Unload a Truck with a Walkie Stacker?

The short answer is: It depends. Walkie stackers are highly useful for specific truck unloading scenarios but may not be the best solution for every situation. They work best for dock-height trailers with accessible pallets and smooth flooring. However, additional equipment may be necessary for deeper or irregularly loaded trucks.

Investing in the right material handling equipment and following best practices ensures efficient, safe, and cost-effective warehouse operations.