Electric Pallet Stackers

-

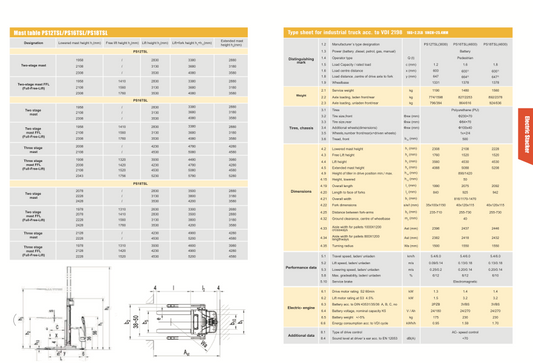

Noblelift Manual Stacker 1000kg 2200lbs

Regular price From $3,000.00Regular priceUnit price / per -

Noblelift Semi-Electric Stacker 1000kg 2200lbs

Regular price From $4,500.00Regular priceUnit price / per -

Noblelift Light Duty Electric Stacker MSL 1000kg 2200lbs

Regular price From $5,999.00Regular priceUnit price / per$6,700.00Sale price From $5,999.00Sale -

Noblelift Edge Lithium Electric Stacker 1200kg 2600lbs

Regular price From $6,950.00Regular priceUnit price / per$9,500.00Sale price From $6,950.00Sale -

Noblelift Heavy Duty Electric Stacker TSL 1600kg/3500lbs

Regular price From $12,200.00Regular priceUnit price / per -

Noblelift Heavy Duty Electric Stacker TSL 1800kg/4000lbs

Regular price From $14,700.00Regular priceUnit price / per -

Noblelift Electric Mini-Counterbalanced Stacker

Regular price From $9,600.00Regular priceUnit price / per$10,500.00Sale price From $9,600.00Sale

Collection: Electric Pallet Stackers

Automated Electric Pallet Stackers: Revolutionize Your Workflow

An electric pallet stacker powered platform is more than just equipment; it’s an investment in your business’s future. Its compact design and ability to handle various mast stackers enhance productivity and safety in storage operations. With attachments such as loaders and sustainable lithium-ion technology, a hoist truck ensures your material handling meets modern demands. It offers efficiency, sustainability, and adaptability, making it essential in warehouses, distribution centers, and manufacturing facilities.

Why Choose an Automated Hoist?

Enhanced Productivity

A powered drive maximizes workflow efficiency by reducing the time and effort needed for lifting and transporting materials. Its advanced motorized system allows operators to move heavy loads effortlessly, enabling faster operations. These machines are invaluable in high-paced environments where quick turnaround is crucial. By automating heavy lifting, businesses can increase throughput while reducing employee strain and fatigue. This allows workers to focus on higher-value tasks, reducing bottlenecks and improving workplace efficiency.

Improved Safety

Safety is crucial in material handling. Mast electric pallet stackers feature ergonomic handles, anti-slip platforms, and precise controls to minimize workplace injuries. Advanced braking systems and stability mechanisms further enhance safety, allowing operators to work with confidence. Intuitive control panels help reduce errors and material mishandling, ensuring a secure work environment. Walkie stackers offer an additional layer of maneuverability, making operations smoother.

Cost-Effective Solution

A lift reduces manual labor and operational costs. By minimizing fatigue and accidents, it cuts downtime and disruptions. Its durable design and low maintenance requirements contribute to long-term savings. Unlike traditional trucks, which require frequent servicing and fuel costs, battery operated stackers offer a cost-efficient, sustainable alternative. These solutions ensure businesses get the most value out of their material handling investments.

Eco-Friendly Operation

A lift truck runs on rechargeable batteries, emitting zero emissions during use. Lithium-ion battery technology enhances energy efficiency, offering longer operating hours with shorter charging times. By switching to electric lift trucks, businesses align with environmental regulations and sustainability initiatives, fostering a greener operation.

Versatile Applications

A handler is ideal for logistics, retail, manufacturing, and construction. Its ability to handle diverse loads and operate in tight spaces makes it indispensable. Whether maneuvering through narrow aisles or transporting heavy inventory, automated electric pallet stackers provide the adaptability needed to tackle operational challenges. Integrating them with smart warehouse systems further optimizes inventory handling and distribution.

Features of a Lift Truck

- Advanced Lifting Technology: Powerful motors and hydraulic systems ensure seamless lifting and lowering, providing stability and precision at various height.

- Compact Design: Ideal for navigating narrow aisles and confined spaces, maximizing warehouse storage efficiency.

- User-Friendly Interface: Intuitive controls allow easy operation, even for first-time users. The ergonomic design reduces strain and enhances control.

- High Load Capacity: Suitable for heavy-duty applications with reinforced frames for a much better capacity and durable construction for reliability.

- Durable Build: Made from robust materials to withstand daily wear and tear, ensuring a long service life and minimal maintenance.

- Energy Efficiency: Equipped with rechargeable batteries that support longer operation hours with minimal downtime.

- Smart Features: Some models include automated guidance systems, load weight sensors, and digital tracking for enhanced efficiency.

Key Use Cases for a Load Truck and Pallet

Warehousing

Electric mast stackers, walk pallet trucks, and counterbalance trucks streamline pallet stacking and inventory organization. They enhance inbound and outbound logistics, optimizing workflows and reducing processing times.

Manufacturing

Transport raw materials and finished goods efficiently, improving production line workflow. jack stackers reduce manual handling reliance, enhancing turnaround times and overall productivity.

Retail Distribution

Manage high stock volumes efficiently, streamlining the supply chain. lifts play a crucial role in timely stock replenishment and inventory management, particularly in crowded storage areas.

Construction

Handle heavy building materials precisely, ensuring projects stay on schedule. Sturdy mast electric pallet stackers easily transport bricks, cement, and other construction materials while maintaining stability and safety.

E-commerce Fulfillment

Optimize order picking and packing in high-demand fulfillment centers. As online shopping rises, automated raiser stackers ensure fast movement of goods, improving delivery times and consumer satisfaction.

Maintaining Your Lift Truck

Proper maintenance ensures a carrier operates efficiently, extending its lifespan and enhancing safety. Follow these maintenance tips to keep your stacker and pallet in top condition:

- Inspect Regularly: Check for capacity, wear and tear on tires, handles, and hydraulic systems daily. Early issue detection by checking at the capacity prevents costly repairs and downtime.

- Charge Batteries Properly: Follow manufacturer guidelines to avoid overcharging or undercharging, preserving battery life and preventing unexpected power failures.

- Clean Thoroughly: Keep the pallet free from debris to prevent operational issues. Dust buildup can interfere with electrical components, reducing efficiency.

- Schedule Professional Servicing: Certified technicians should perform periodic servicing to identify and fix potential problems before they escalate, ensuring optimal operation.

- Train Your Team: Provide operators with proper training to ensure safe, efficient usage. Educating employees on best practices minimizes accidents and enhances workplace productivity.

By investing in pallet stacker and maintaining them properly, businesses achieve seamless material handling with increased efficiency, safety, and cost-effectiveness. View our range of automated boom stackers today to learn and request a quote to take your material handling to the next level with our electric pallet stackers! Ensure your business benefits from the best customer solutions available while reducing operational costs. Our automated stackers provide an excellent lbs - to - capacity ratio, delivering powerful performance for diverse applications.